Reduces Strain and Fatigue

Supports easier lateral picks and repetitive manual tasks.

Potential downstream effects of reduced lateral friction. Results vary by application.

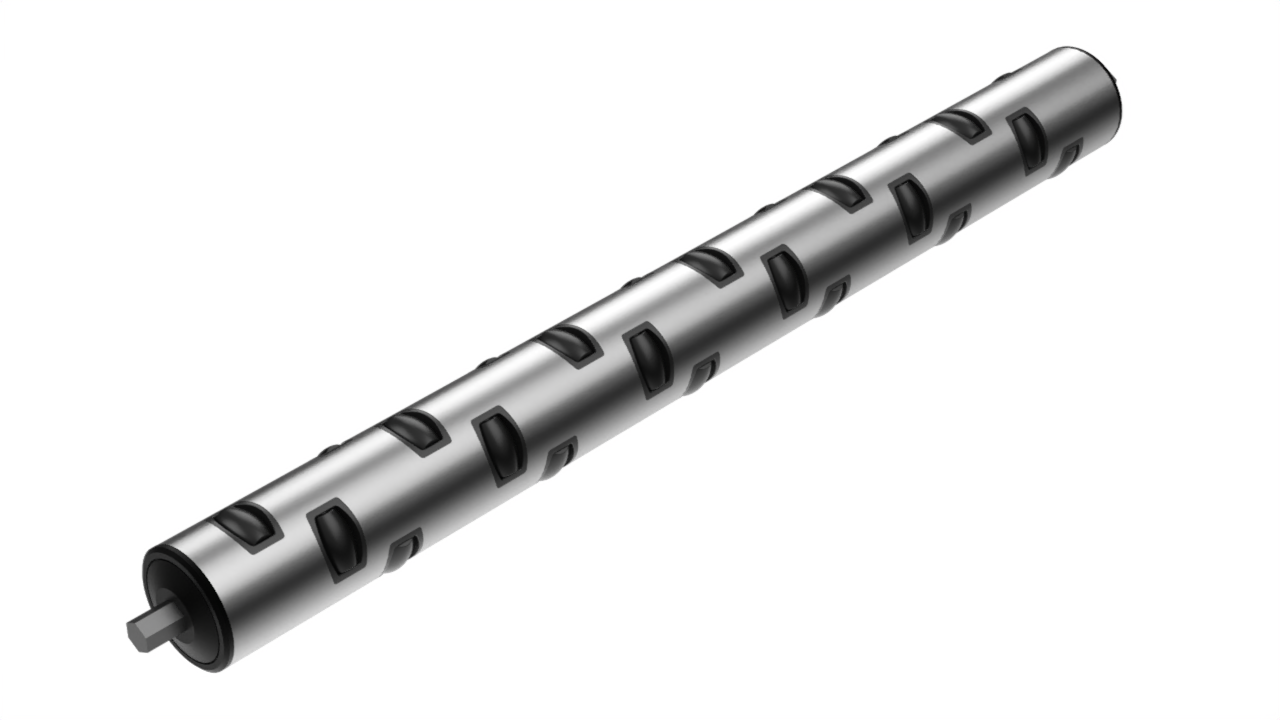

Omni Metalcraft RSL’s VectoRoller™ patent-pending design features proprietary wheels that can be mounted at rates of up to 2 wheels per inch of effective tube width, allowing lateral friction performance to be configured for a specific application.

1.9” OD FLO-COAT TUBING

Triple-layer coating delivers corrosion resistance and superior cosmetics while maintaining strength and durability.

ENGINEERED VECTOROLLER™-WHEELS

Our proprietary individual VectoRoller™ wheels are mounted perpendicular to the direction of roller rotation to significantly reduce the friction during movement along the roller face.

ABEC BEARINGS

Precision bearings for increased load capacity, speed and durability to maximize life in high-performance applications.

7/16” SPRING-RETAINED HEX AXLE

Optimizes ease of installation while maintaining durability.

DRIVE CONFIGURATION OPTIONS

Fully customizable to include groove profiles for O-rings and poly-ribbed hubs for multi-ribbed belts.

Click on a VectoRoller™ configuration below to enlarge the image

The VectoRoller™ outperforms traditional and alternative solutions in four key categories:

Whether you’re upgrading existing infrastructure or building new systems, VectoRoller™ offers a smarter, more ergonomic, and scalable solution engineered to reduce strain and increase flow.

| Ease of Installation | Maintenance Friendly Features | Optimized Load Capacity | Gravity and Powered Solutions | |

|---|---|---|---|---|

| VectoRoller™ | ||||

| Ball Transfer Tables | ||||

| Omnidirectional Skatewheel | ||||

| Omnidirectional Flowrail | ||||

| Automated Solutions |

| Excellent | Average | N/A |

|---|---|---|

The VectoRoller’s™ unique design delivers up to an 80% reduction in the energy required to laterally intercept and pick packages when compared to legacy products!

Example shown represents the force required to move a 50lb tote laterally across the surface of each product.